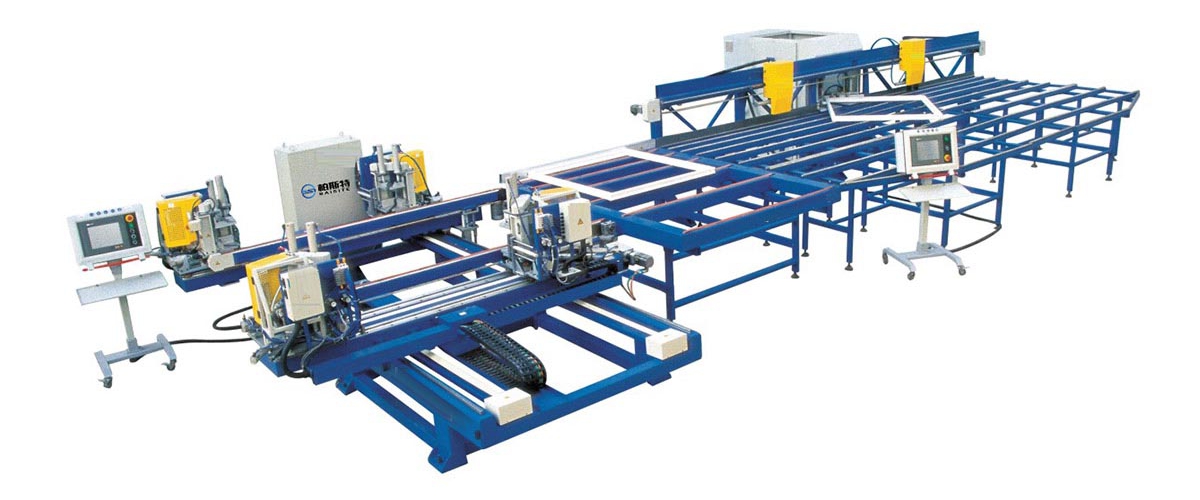

Automatic Welding/ Cleaning Production Line-AWCL-100

Automatic Welding/ Cleaning Production Line-AWCL-100

Function

For high-standard European window and door welding and cleaning.

Main Features

Composed of welding unit, automatic conveying unit and corner cleaning unit.

Horizontal structure with strengthened rigidity design for stable operation.

With imported servo system, industrial-grade computer control, high stability

Automatic programming and selection of processing programs, which makes

CAD/CAPP/CAM available

Bar code reader is optional, to get processing data by barcode reading

With optimized Welding-Transferring -Cleaning processing procedure, high efficiency

Features of Welding units

Feeding system of welding head adopts motion square guide rail for good stability and reliability.

Unique forced synchronization technology with special know-how which increases the strength and quality of the welding corners.

Unique clamping and heating integrated structure as well as square rail motion pair

The machine head adopts double synchronous belt transmission mechanism, high positioning accuracy

With automatic size compensation, which makes high accuracy of finished product sizes

Quick-change magnetic fixtures to improve work efficiency

Automatic discharging system for double-stack welding to keep machine working more stably and reliably.

Double stack frame or sash welding are available as required

Features of Cleaning Units

With servo system to clean the welding seams automatically

With quick corner-turning structure and inside clamping to improve work efficiency

Upside-down cylinder installation on Tool mechanism

Automatic identification of profiles and selection of cleaning programs

More than 100 different types of profiles can be processed without changing tools

Compensations on arc and straight line makes the corner nice and clean

Transferring and profile Gripper

After welding, the windows will be sent to the corner cleaner automatically

Double gripper design with servo drive control, square rail motion par ,high efficiency

Unique Gripper holding design to make the loading and feeding quick and accurate .

Main Parameter

Input Voltage 3P 380V, 50 HZ

Input Power 15 kW

Air Pressure 0.5~ 0.8 MPa

Air Consumption 300L/min

Welding height 30mm~130mm

Welding Width 30mm~120mm

Processing range 450mm×400mm~2400mm×3000mm

Overall Dimensions 14500mm x 5000mm x 2000 mm

Weight 6000 kg

Hotline:

Hotline: